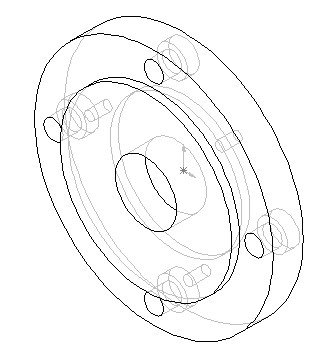

Last night, Mike and I got about halfway through making the adapter plate for the 4 jaw chuck. We used the big lathe at work (a South Bend 9×40?), so cutting the aluminum plate was like cutting butter. I got a little over-enthusiastic (exactly 3 thousandths of an inch too enthusiastic, to be exact) with one of the cuts, so when you mounted the 4 jaw chuck on that shoulder, it wiggled just the littlest bit. Mike showed me an awesome trick to fix it – we went around that shoulder with a prick punch and put tiny little holes in the metal, which pushed enough of it up that the chuck fit perfectly. We’ll have to attach it semi-permanently with Locktite so the holes don’t collapse, but it saved a hour and half’s worth of work & $10 in aluminum.

So what’s left to do is set it up on the mill and drill the holes for the various screws – really it shouldn’t be too hard since the machine has digital readouts (DRO’s) that make finding the precise location of holes very easy. I did a drawing in SolidWorks so I could print out the exact coordinates of the holes. Almost there…